- Sorry, this product cannot be purchased.

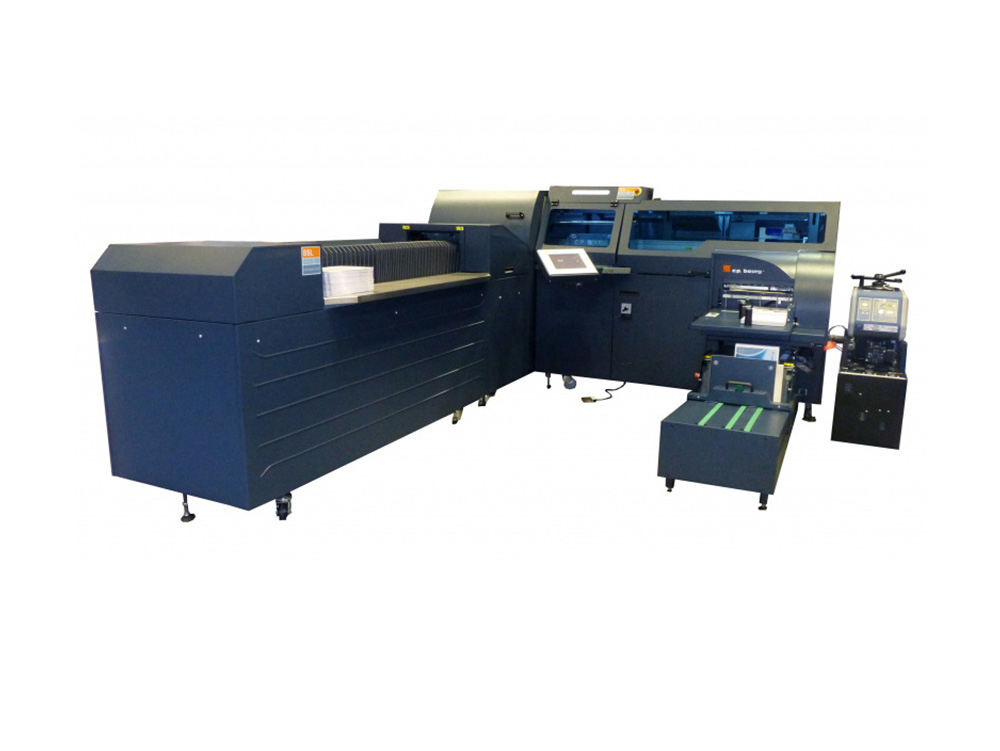

CP BOURG BINDER BB3002 EVA

Additional Information

CP BOURG BINDER BB3002 EVA

Specification :

| 1 | MEDIA | |

| Maximum speed | 650 cycles/hour 350 books/hour (operator dependent) | |

| COVER | ||

| Minimum cover size | 100 x 201 mm (3.93 x 7.91 in) | |

| Maximum cover size | 385 x 750 mm (15.15 x 29.52 in) | |

| Cover weight | 80 to 300 gsm | |

| CONTENT | ||

| Minimum paper size of books with cover (perfect binding mode) | 100 x 90 mm (3.93 x 3.54 in) | |

| Maximum paper size of books with cover | 385 x 380 mm (2.36 x 3.54 in) | |

| Minimum paper size of books without cover (padding mode) | 60 x 90 mm (2.36 x 3.54 in) | |

| Maximum paper size of books without cover (padding mode) | 385 x 320 mm (15.15 x 12.59 in) | |

| Book thickness | 1 to 60 mm (0.04 to 2.36 in) | |

| Milling depth | 0 to 3 mm (0 to 0.11 in) | |

| Paper weight | 60 to 160 gsm | |

| 2 | PHYSICAL | |

| Dimensions BB3002 (L x W x H) | 202 x 135 x 150 cm (79.52 x 53.15 x 59.05 in ) | |

| Dimensions BBR (L x W x H) | 106 x 60 x 50 cm (41.73 x 23.62 x 19.68 in) | |

| Weight BB3002 | 650 Kg (1,430 lbs) | |

| Weight BBR | 80 Kg (176 lbs) | |

| Glue temperature | 130 to 180 °C (266 °F to 356 °F) | |

| Cover station capacity / cover pile height | 80 mm (3.15 in) | |

| BBR capacity | 700 mm (27.56 in) | |

| 3 | ELECTRICAL / ACOUSTIC | |

| Power supply | 208/220V ± 10%, 60 Hz, 3 phase delta, 12A 220/230 or 240V ± 10%, 50 Hz, 3 phase delta, 12A 380/400 or 415V ± 10%, 50 Hz, 3 phase star, no neutral needed, 12A | |

| OPERATIONAL MODE | ||

| Power consumption | 4,000 W | |

| Radiant heat | 13,648 BTU/hour | |

| Sound level | 76 dB | |

| STANBY MODE | ||

| Power consumption | 1,500 W | |

| Radiant heat | 5,120 BTU/hour |

Standard Feature

| FEATURES | ADVANTAGES | BENEFITS |

| FULLY AUTOMATED BINDER | Adapts all features automatically to the thickness of each job | – Ideal for variable data jobs varying in thickness and on-demand jobs – All functionalities can be controlled via the GUI |

| WIDE RANGE OF BOOK THICKNESSES | Binds from 1 to 60 mm (0.04 to 2.36 in) | – No pre-measurements required – Book thickness is automatically recorded during the loading process |

| GRAPHICAL USER INTERFACE (GUI) | – User-friendly industrial grade color touch screen – Single GUI for entire finishing line can be connected wirelessly to any tablet, smartphone or computer | – Easy to use interface – Control your entire finishing remotely – Remote diagnostics, statistics and much more |

| MISSING COVER DETECTION | Check that the cover has been taken | – Avoid binding without cover – Avoid reprints and waste |

| ADJUSTABLE JOGGER VIBRATION | Vibration of the the jogger plate re-aligns the block of paper to be bound | Ensures high quality perfect bound books |

| SUPERIOR MILLING AND NOTCHING | Power milling wheel with notching for EVA applications (milling depth: from 0 to 3 mm – from 0 to 0.11 in) | Ensures deep glue penetration for maximum cover adhesion |

| PAPER DUST COLLECTOR | Gathers paper dust generated by milling/notching operation | No need for external dust removal |

| 3 CYLINDER GLUE TANK | – 1st cylinder penetrates between sheets – 2nd cylinder applies desired spine glue quantity – 3rd cylinder guarentees perfect glue repartition | Superior EVA spine gluing for premier book binding |

| DETECTION OF MIN/MAX GLUE LEVELS | Indicates when the glue tank needs to be refilled | – Manage glue level more easily – Gain in productivity |

| INCORPORATED SIDE GLUING | Adjustable side gluing (accuracy at 0,1 mm/0.004 in) | Superior EVA side gluing for premier book binding |

| KNIFE CREASING | Up to 13 positive/negative cover creases | – Highest quality creasing – Able to create winged books |

| START-UP TIMER | Enables to pre-program and schedule production | – Gain time : no need to wait for the glue to be ready to operate – Fully automatic: no need to switch on the machine |

| SAFETY BARRIER | – Light curtains guarantee operator safety while loading – Jobs are automatically processed when removing hands from loading area | Increases productivity and ease of operation while guaranteeing operator safety |

Options

| FEATURES | ADVANTAGES | BENEFITS |

| DOUBLE COVER DETECTION | Check that cover feeder takes one cover at a time | – No manual check that only one cover has been taken – Avoid reprints and waste |

| AUTOMATIC BARCODE SCANNING | – Each book block and cover will be scanned in order to guarantee book integrity – No setup required

| – Each job is checked in order to avoid reprints, also records each job for job tracking – No manual job setup |

| BOURG BOOK RECEPTION MODULE (BBR) | Stacks books vertically on the spine to allow the glue to dry in a perfect position | – Large storage capacity – No production loss as it can be unloaded during job production – Guarantees book spine squareness |